- By Admin

-

Construct Ion

-

0 Comments

- Industry News

- 544

YIIING MACEINFRY Unveils Next-Gen Plate Heat Exchanger Solutions: Pioneering Efficiency in Global Industrial Thermal Management

Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) announces its innovative range of plate heat exchangers. Discover high-efficiency detachable, brazed, and fully-welded models engineered for superior thermal management, ISO-certified quality, and global sustainability goals. Visit www.yuling-phe.com.

YIIING MACEINFRY Unveils Next-Gen Plate Heat Exchanger Solutions: Pioneering Efficiency in Global Industrial Thermal Management

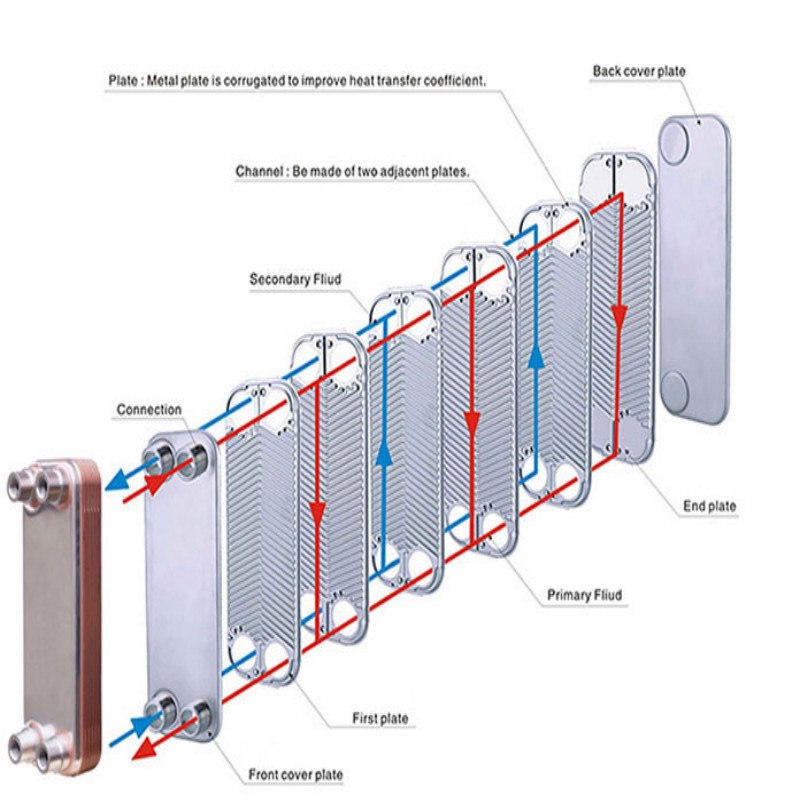

Haian, Jiangsu, China – In an era defined by the urgent global pursuit of energy efficiency and carbon reduction, advanced thermal management has become a critical competitive differentiator across industries. Jiangsu Yuling Machinery Technology Co., Ltd., operating under its distinguished brand YIIING MACEINFRY, announces a strategic expansion of its innovative portfolio of plate heat exchanger solutions. Building upon its acclaimed position as a top-tier Chinese manufacturer, Yuling is setting new benchmarks in performance, durability, and application-specific engineering for detachable plate heat exchangers, brazed plate heat exchangers, and fully-welded plate heat exchangers.

The Industrial Imperative: Why Advanced Thermal Exchange Matters Now

Recent global dynamics, including volatile energy prices and stringent environmental regulations like the EU's Green Deal, have accelerated the adoption of high-efficiency heat recovery systems. Industries from chemical processing and pharmaceuticals to marine engineering and district heating are actively retrofitting their infrastructure. The core of this upgrade often lies in the plate heat exchanger, a device whose efficiency directly impacts operational costs, energy consumption, and environmental footprint. Unlike traditional shell-and-tube models, modern plate designs offer superior heat transfer coefficients in a compact footprint, making them indispensable for sustainable industrial operations.

The modern headquarters and production facility of Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY), a center for thermal engineering excellence.

YIIING MACEINFRY's Engineering Edge: Beyond Manufacturing

As a National High-Tech Enterprise and the home of the Yuling Thermal Energy Technology Research Institute, YIIING MACEINFRY transcends the role of a simple parts supplier. The company's philosophy is rooted in integrated R&D and precision manufacturing. This approach is validated by its comprehensive suite of international certifications, including ISO 9001:2015 for Quality Management, ISO 14001:2015 for Environmental Management, and ISO 45001:2018 for Occupational Health & Safety—all specifically for heat exchanger production.

ISO 9001:2015

Quality Management

ISO 45001:2018

Health & Safety Management

ISO 14001:2015

Environmental Management

Spotlight on Innovation: Core Product Lines Redefining Performance

YIIING MACEINFRY offers a holistic range of thermal solutions designed to meet the most demanding specifications, providing a viable and often superior alternative to established brands like Alfa Laval plate heat exchangers, Tranter plate heat exchangers, and Sondex plate heat exchangers.

1. High-Efficiency Detachable (Gasketed) Plate Heat Exchangers

Ideal for applications requiring regular inspection or cleaning, such as in the food & beverage or pharmaceutical sectors. Yuling's series (e.g., A10, A50, A150, A220) feature customizable plate heat exchanger plates in materials like SUS316L, Titanium, or Hastelloy, paired with a wide selection of plate heat exchanger gaskets (NBR, EPDM, Viton) to handle everything from purified water to concentrated acids. Their design achieves terminal temperature differences as low as 1°C, maximizing waste heat recovery potential.

2. Robust Brazed Plate Heat Exchangers

An evolution beyond gasketed models, Yuling's ZL series (including ZL20B, ZL52A, ZL95B) utilizes vacuum copper or nickel brazing for a leak-proof, compact, and high-pressure-resistant unit. With a design pressure up to 4.5MPa and exceptional thermal performance, these are perfect for refrigeration, HVAC, and power electronics cooling. They offer a footprint and efficiency comparable to leading SWEP plate heat exchangers and GEA plate heat exchangers.

3. Heavy-Duty Fully-Welded Plate Heat Exchangers

For the most challenging processes involving high temperatures, high pressures, or aggressive media where gaskets would fail. This design merges the efficiency of plate technology with the durability of welded construction, suitable for applications in chemical synthesis and waste heat recovery from exhaust gases, offering an alternative to specialized units from API plate heat exchangers or Hisaka plate heat exchangers.

From the Factory Floor: A Commitment to Precision

The company's manufacturing prowess is evident in its advanced workshops equipped with large-scale CNC processing centers. This capability ensures the precise fabrication of corrugated plate heat exchanger plates, which are critical to optimizing fluid turbulence and heat transfer coefficients.

Precision CNC machining at Yuling's facility ensures the highest quality standards for every component.

Expert Insight: Engineering for a Sustainable Future

"The global market is no longer just about buying a component; it's about partnering for a solution," explains a lead researcher at the Yuling Thermal Energy Technology Research Institute. "Our development of brazed and fully-welded plate heat exchangers is directly responsive to trends in electrification, carbon capture, and circular economy models. For instance, our units are pivotal in recovering low-grade waste heat, turning an energy loss into a valuable asset. We engineer our products not just to match but to anticipate the needs that brands specifying APV plate heat exchangers or Alfa Laval plate heat exchangers are facing today."

Connect with YIIING MACEINFRY

For engineers, project managers, and procurement specialists seeking reliable, efficient, and innovative thermal management solutions, Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) invites collaboration.

- Explore Our Solutions: www.yuling-phe.com

- Telephone: +86 513 8836 0268

- Fax: 0513-88363196

- WhatsApp: +86 13813790595

- Email: info@yuling-machine.com

- Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.

About Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY): A national high-tech enterprise and a leading private science and technology company in Jiangsu Province, specializing in the R&D, production, sales, and service of various heat exchangers and equipment. With its Yuling Thermal Energy Technology Research Institute and a commitment to international quality standards, the company delivers advanced thermal exchange solutions to a global market, driving efficiency and sustainability across industries.