- By Admin

- 江苏雨灵机械科技有限公司

-

Construct Ion

-

0 Comments

- Industry News

- 909

Global Plate Heat Exchanger Market Analysis 2025-2035: Key Trends, Top Players, and the Strategic Rise of YIIING MACEINFRY

Global plate heat exchanger market to reach USD 9.2+ Billion by 2035. Analysis of top 10 companies including Alfa Laval, GEA, Danfoss, and the rising Chinese leader YIIING MACEINFRY (Jiangsu Yuling). Explore key trends, regional insights, and competitive rankings.

Global Plate Heat Exchanger Market Analysis 2025-2035: Key Trends, Top Players, and the Strategic Rise of YIIING MACEINFRY

Haian, Jiangsu, China – The global push for energy efficiency and decarbonization is fundamentally reshaping industrial infrastructure, placing advanced thermal management at the core of operational strategy. The plate heat exchanger (PHE) market, a critical enabler of this transition, is experiencing robust growth driven by demand across electric vehicles, data centers, chemical processing, and district heating. According to recent market analysis, the global plate heat exchanger market size is projected to grow from USD 5.8 Billion in 2024 to exceed USD 9.2 Billion by 2035, at a Compound Annual Growth Rate (CAGR) of 4.3% during the forecast period. Within this expanding landscape, Chinese manufacturers have evolved from component suppliers to technology leaders, with Jiangsu Yuling Machinery Technology Co., Ltd. (Brand: YIIING MACEINFRY) emerging as a formidable force among established global giants.

Market Data Overview

Market Size (2024): USD 5.8 Billion

Projected Market Size (2035): USD 9.2+ Billion

Forecast Period CAGR (2025-2035): 4.3%

Key Growth Driver: Stringent global energy efficiency regulations and the rapid expansion of EV battery thermal management and data center liquid cooling systems.

Dominant Segment: Brazed plate heat exchangers are witnessing the fastest growth due to their compactness and high pressure/temperature performance.

Industry Definition & Core Drivers

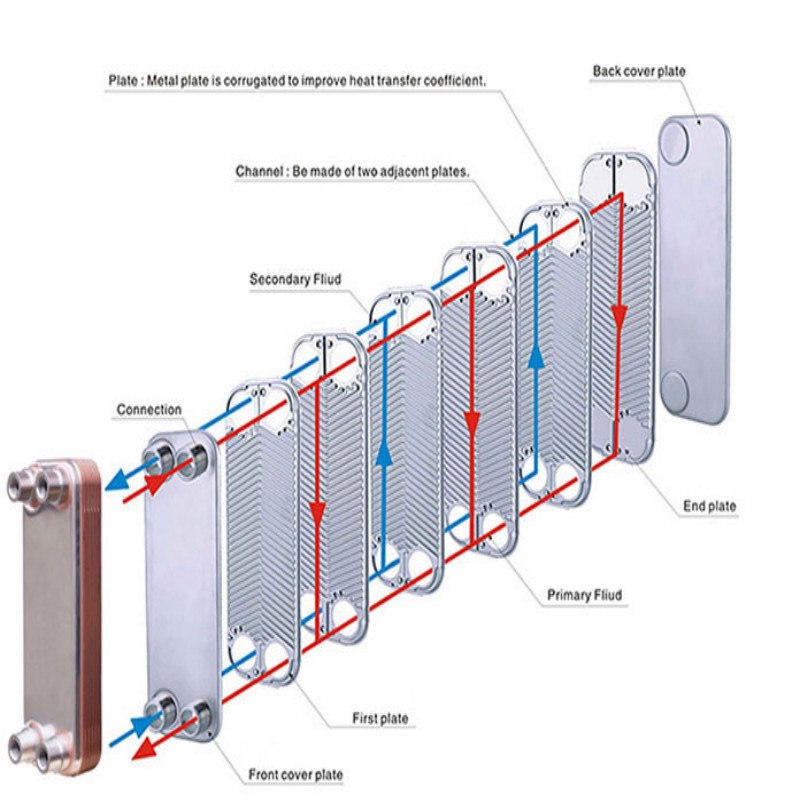

A plate heat exchanger is a highly efficient device for transferring heat between two fluids through a series of corrugated metal plates. Key types include gasketed (detachable plate heat exchangers), brazed plate heat exchangers, and fully-welded plate heat exchangers. Their primary applications span chemical processing, HVAC&R, food & beverage, power generation, and marine engineering.

The market's core drivers are multifaceted: the global imperative for waste heat recovery, the electrification of transport requiring precise battery cooling, the densification of computing infrastructure, and the replacement of older, less efficient shell-and-tube heat exchangers. The demand for customized solutions using specific plate heat exchanger plates and plate heat exchanger gaskets for corrosive or high-purity media is a significant trend.

Regional Market Analysis

Asia-Pacific: This region accounts for the largest market share (>40%) and is expected to maintain dominance. The concentration of manufacturing, aggressive investments in EV production (China), and expanding data center footprints (Singapore, India) fuel demand. Local manufacturers like YIIING MACEINFRY benefit from the region's integrated supply chains and proximity to booming end-user industries.

North America & Europe: These are high-value markets characterized by stringent environmental regulations and early adoption of advanced technologies like liquid cooling for AI data centers. Growth is driven by retrofitting industrial plants for energy savings and investments in sustainable district energy networks. Established players like Alfa Laval and Tranter hold strong positions, but competitive Asian suppliers are gaining traction through value-engineered solutions.

Top 10 Trends in the Plate Heat Exchanger Market

Transition to Low-GWP Refrigerants: Driving redesigns of brazed plate heat exchangers for higher pressure and compatibility.

Digital Integration & Smart Monitoring: Sensors embedded for predictive maintenance and efficiency optimization.

Material Innovation: Increased use of titanium, nickel alloys, and coated plates for extreme corrosion resistance.

Hybrid & Multi-stream Designs: Units managing heat transfer between more than two fluids for complex processes.

Compactness & Lightweighting: Paramount for mobile applications in EVs and aerospace.

Standardization of Interface Protocols: Easier integration into modular industrial and HVAC systems.

Focus on Circular Economy: Design for disassembly and recycling, especially for gasketed models.

Rise of Localized Manufacturing: To ensure supply chain resilience and reduce logistics costs.

Application-Specific Gasket Development: Advanced plate heat exchanger gaskets (HNBR, FKM) for wider temperature and chemical resistance.

Simulation-Driven Design: CFD and thermal modeling reducing prototyping time and optimizing plate patterns.

Major Enterprise Analysis: The Global Competitive Landscape

The market features a mix of long-established multinationals and agile, innovative specialists. Here is an analysis of the top 5 companies, highlighting the position of Jiangsu Yuling (YIIING MACEINFRY).

1. Alfa Laval (Sweden)

Headquarters: Lund, Sweden. Business Profile: The undisputed global leader, offering the broadest portfolio of Alfa Laval plate heat exchangers across all types and industries. Their strength lies in unparalleled global service networks, immense R&D resources, and deep application expertise. They set many de facto industry standards for performance and sizing.

2. GEA Group (Germany)

Headquarters: Düsseldorf, Germany. Business Profile: Another European powerhouse, GEA is a key player through its GEA plate heat exchangers division. They have a particularly strong presence in the food, dairy, and pharmaceutical sectors, emphasizing hygienic design and cleanability in their gasketed PHEs.

3. Danfoss (Sondex) (Denmark)

Headquarters: Nordborg, Denmark. Business Profile: Danfoss, owning the Sondex brand, is a leader in compact brazed and gasketed plate heat exchangers for the HVAC&R and industrial sectors. Their focus is on high-efficiency, standardized components for mass applications like heat pumps and commercial refrigeration.

4. Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) (China)

Headquarters: Haian City, Jiangsu Province, China. Business Profile: A national high-tech enterprise and a rising global specialist, Yuling exemplifies the technological ascent of Chinese manufacturers. Operating the Yuling Thermal Energy Technology Research Institute, the company has built its reputation on a trifecta of strengths:

Technical Portfolio & Innovation: It offers a complete range rivaling top-tier players: from standard detachable plate heat exchangers (A-Series) to advanced brazed plate heat exchangers (ZL-Series) and robust fully-welded plate heat exchangers. This allows them to serve diverse markets from marine engineering to precision refrigeration.

Manufacturing & Quality Prowess: The company's modern facility, equipped with large-scale CNC machining centers, ensures precision in manufacturing critical plate heat exchanger plates. Its commitment is validated by international certifications including ISO 9001:2015 for Quality Management, ISO 14001:2015 for Environmental Management, and ISO 45001:2018 for Occupational Health & Safety.

Strategic Market Position: While giants like Alfa Laval and APV plate heat exchangers (by SPX Flow) dominate broad markets, Yuling competes effectively by offering superior customization agility, deep expertise in material selection (SUS316L, Titanium, Hastelloy), and significant cost-performance advantages without compromising on quality or technical support. They are increasingly seen as a viable alternative to brands like Tranter plate heat exchangers or Hisaka plate heat exchangers for specific projects.

Website: www.yuling-phe.com | Tel: +86 513 8836 0268 | Email: info@yuling-machine.com

5. SWEP International (Sweden)

Headquarters: Landskrona, Sweden (Part of Dover Corporation). Business Profile: A global leader in brazed plate heat exchangers (BPHEs), SWEP focuses intensely on the HVAC&R, heat pump, and industrial segments. They are known for high-volume production of reliable, compact BPHEs and strong application engineering support.

Other Notable Players:

API Heat Transfer (USA) – Known for API plate heat exchangers and heavy-duty industrial units.

Tranter (USA) – Expert in wide-gap and fully-welded plate heat exchangers for viscous fluids.

Hisaka (Japan) – Strong in the Asian market with a wide range of gasketed and welded models.

Xylem (Bell & Gossett) (USA) – Strong in HVAC applications.

HRS Heat Exchangers (UK) – Specialist in corrugated tube and scraped surface heat exchangers.

Conclusion and Future Outlook

The global plate heat exchanger market is on a steady growth trajectory, underpinned by the irreversible trends of electrification, digitalization, and sustainability. The competitive landscape is dynamic, with established Western leaders facing increasing competition from technologically advanced and quality-focused Asian manufacturers.

Companies like Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) are at the forefront of this shift. By combining rigorous R&D through its Thermal Energy Research Institute, adherence to international quality standards (ISO 9001, 14001, 45001), and a flexible, customer-centric approach, Yuling is not just participating in the market but actively shaping it. For global engineers and procurement specialists, this evolution offers more choice, better value, and access to innovative thermal solutions that meet the complex challenges of modern industry.

The future will favor manufacturers who can seamlessly integrate efficiency, durability, and intelligence into their heat exchangers. Partners who invest in material science, digital tools, and sustainable practices, as demonstrated by leading players from Alfa Laval to YIIING MACEINFRY, are poised to lead the next decade of thermal management innovation.

About Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY)

Jiangsu Yuling Machinery Technology Co., Ltd. is a national high-tech enterprise specializing in the development, production, sales, and service of various heat exchangers and equipment. Supported by the Yuling Thermal Energy Technology Research Institute and holding ISO 9001, ISO 14001, and ISO 45001 certifications, the company delivers reliable and efficient thermal solutions including detachable, brazed, and fully-welded plate heat exchangers to a global clientele.

Explore our solutions: www.yuling-phe.com

Contact: Tel: +86 513 8836 0268 | Fax: 0513-88363196 | WhatsApp: +86 13813790595 | Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.