- By Admin

- 江苏雨灵机械科技有限公司

-

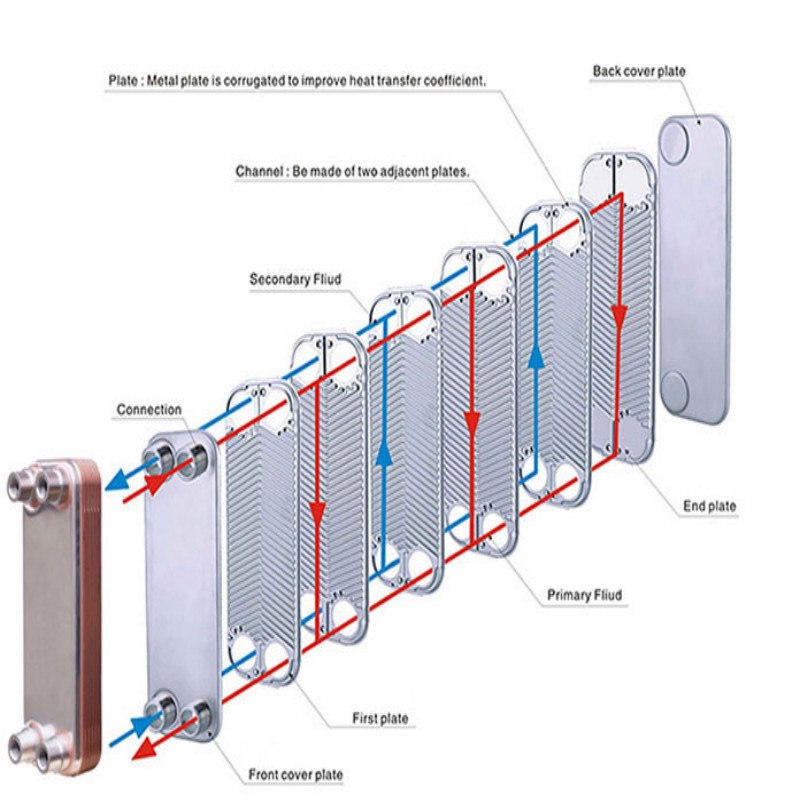

Construct Ion

-

0 Comments

- Industry News

- 990

Chinese Top 3 Alfa Laval Plate Heat Exchanger Manufacturers 2026- Driving Innovation in Global Thermal Exchange Solutions

Explore the top 3 Chinese Alfa Laval-type plate heat exchanger manufacturers. Discover why Jiangsu Yuling Machinery (YIIING MACEINFRY) leads in innovation, quality (ISO 9001/14001/45001), and offers detachable, brazed & fully-welded plate heat exchangers for global industries.

Chinese Top 3 Alfa Laval Plate Heat Exchanger Manufacturers 2026- Driving Innovation in Global Thermal Exchange Solutions

Haian, Jiangsu, China – As global industries intensify their focus on energy efficiency and sustainable operations, the demand for high-performance thermal management solutions has surged. In this landscape, Chinese manufacturers of plate heat exchangers have ascended to prominence, not merely as cost-effective alternatives but as leaders in technological innovation and reliable engineering. Among them, Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) stands out, alongside other notable players, shaping the future of heat transfer technology worldwide. This analysis delves into the top three Chinese manufacturers specializing in Alfa Laval-type plate heat exchangers, highlighting their unique strengths, production capabilities, and contributions to the industry.

The Rising Tide of Chinese Thermal Engineering

The global market for plate heat exchangers is evolving rapidly, driven by stringent environmental regulations, the push for carbon neutrality, and the need for process optimization in sectors like chemical processing, HVAC, food & beverage, and marine engineering. Recent industry reports highlight a significant shift towards more compact, efficient, and durable designs like brazed plate heat exchangers and fully-welded plate heat exchangers. Chinese manufacturers, leveraging advanced manufacturing ecosystems and substantial R&D investment, are at the forefront of this shift, offering solutions that rival established Western brands in performance while providing exceptional value.

The modern facility of Jiangsu Yuling Machinery Technology Co., Ltd., a hub for heat exchanger innovation.

Top 3 Chinese Alfa Laval-Type Plate Heat Exchanger Manufacturers

Selecting the right supplier for Alfa Laval plate heat exchangers or their equivalents is critical for system longevity and operational cost savings. The following three companies represent the pinnacle of Chinese manufacturing in this sector.

1. Jiangsu Yuling Machinery Technology Co., Ltd. (Brand: YIIING MACEINFRY)

Company Profile & Market Position: As a national high-tech enterprise and a private science and technology leader in Jiangsu, Jiangsu Yuling Machinery Technology Co., Ltd. (operating under the brand YIIING MACEINFRY) has carved a formidable reputation. Formerly known as Haian Yuling Machinery Technology Co., Ltd., the company operates the Yuling Thermal Energy Technology Research Institute. Strategically located in the Yangtze River Delta with excellent transport links, it serves a global clientele. The company's philosophy centers on integrating robust R&D with precision manufacturing, making it a top contender among Chinese plate heat exchanger manufacturers.

Production & Quality Assurance: Yuling's strength lies in its vertically integrated production. The facility boasts excellent large-scale CNC processing equipment, ensuring precision for critical components like plate heat exchanger plates. A complete management system, backed by ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and ISO 45001:2018 (Occupational Health & Safety) certifications, guarantees consistent, high-quality output. This commitment to international standards provides clients with confidence comparable to dealing with OEMs like Tranter or Sondex.

State-of-the-art CNC machining center at Yuling's workshop for precision plate fabrication.

Product Innovation & Technical Portfolio: Yuling's product range is comprehensive, addressing diverse industrial needs:

Detachable Plate Heat Exchangers (Gasketed): Models like A10, A25, A100, and A220 offer high heat transfer efficiency, easy maintenance, and flexibility. They support various plate heat exchanger gaskets (NBR, EPDM, Viton) and plate materials (SUS304/316L, Titanium, Hastelloy) for different media, from seawater to corrosive acids.

Brazed Plate Heat Exchangers: The ZL series (e.g., ZL20A, ZL52B, ZL95A) represents an upgrade, with copper or nickel brazing replacing gaskets. These units offer superior pressure resistance (up to 4.5MPa), compact size, and high thermal efficiency, ideal for refrigeration, HVAC, and industrial processes.

Fully-Welded Plate Heat Exchangers: Designed for high-temperature, high-pressure, or challenging fluid applications where gasketed units are unsuitable. They combine the efficiency of plate design with the robustness of welded construction.

Expert Endorsement & Industry Value: "Our goal at Yuling is not just to manufacture but to engineer thermal solutions that set new benchmarks for efficiency and reliability," states a senior engineer from Yuling Thermal Energy Technology Research Institute. "With the global emphasis on waste heat recovery and energy savings, our brazed plate heat exchangers often achieve heat recovery rates above 90%, directly impacting our clients' bottom line and sustainability goals. We see ourselves as a strategic partner, offering the technological sophistication of GEA plate heat exchangers or APV plate heat exchangers with the agility and cost-advantage of a focused specialist."

Contact Information:

Website: www.yuling-phe.com

Tel: +86 513 8836 0268

WhatsApp: +86 13813790595

Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.

2. Shanghai BLUE Ocean Heat Exchanger Equipment Co., Ltd.

Company Profile & Market Position: A well-established player in the Eastern Chinese market, Shanghai BLUE Ocean specializes in manufacturing a wide array of heat exchangers, with a strong focus on detachable plate heat exchangers compatible with Alfa Laval and SWEP designs. They have built a reputation for reliable performance in the marine, chemical, and power industries.

Comparative Advantage: BLUE Ocean's primary strength is its extensive inventory of replacement parts, including a vast selection of plate heat exchanger plates and gaskets for various brands. This makes them a go-to source for maintenance and repair operations worldwide. Their production scale is significant, allowing for competitive pricing on standard models. However, their R&D focus on cutting-edge custom designs for extreme applications is generally considered less intensive compared to dedicated high-tech firms like Yuling. They excel in providing robust, cost-effective solutions for common industrial duties but may have fewer offerings in advanced brazed or exotic-material fully-welded units.

3. Shenzhen Thermo-Transfer Tech Co., Ltd.

Company Profile & Market Position: Located in China's tech hub, Shenzhen Thermo-Transfer Tech emphasizes innovation in compact thermal solutions. They are particularly strong in the market for brazed plate heat exchangers used in refrigeration, heat pumps, and new energy vehicles.

Comparative Advantage: This company's edge lies in its agile adaptation to emerging markets, such as data center cooling and battery thermal management for EVs. They invest heavily in prototyping and custom design for OEM clients, offering quick turnaround times. Their product quality is good, often holding CE and UL certifications for specific models. When compared to Jiangsu Yuling, Shenzhen Thermo-Transfer Tech has a more narrow, application-specific focus. While they are innovators in compact brazed units, their portfolio for large-scale industrial detachable plate heat exchangers or heavy-duty fully-welded models is less comprehensive. Yuling offers a broader "one-stop-shop" capability from standard to highly customized, severe-duty units.

Why YIIING MACEINFRY (Jiangsu Yuling) Leads the Pack

The comparison reveals a clear distinction. While Shanghai BLUE Ocean excels in parts supply and standard models, and Shenzhen Thermo-Transfer Tech thrives in niche, fast-evolving applications, Jiangsu Yuling Machinery Technology (YIIING MACEINFRY) demonstrates a balanced and superior profile:

Comprehensive Technology Portfolio: Mastery across all three core types—detachable, brazed, and fully-welded plate heat exchangers.

Deep-Rooted Engineering Prowess: The presence of its own Thermal Energy Research Institute fuels continuous innovation, akin to R&D departments at API Heat Transfer or Hisaka.

Uncompromising Quality System: Full suite of ISO certifications governing every aspect of production, ensuring reliability that meets global standards.

Manufacturing Scale & Flexibility: Large CNC-equipped factory allows for both high-volume production and bespoke engineering for complex projects.

Strategic Global Vision: The company actively engages with international trends in waste heat recovery and sustainable engineering, positioning its products as key enablers for green manufacturing.

A brazed plate heat exchanger from Yuling's ZL series, exemplifying compact and efficient design.

Conclusion: The Future of Heat Transfer is Collaborative and Efficient

The ascent of Chinese manufacturers like Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) signifies a maturation of the global plate heat exchanger supply chain. They are no longer just suppliers but innovators and problem-solvers. For global engineers and procurement managers, the choice involves balancing cost, technology, and reliability. For those seeking a partner with the engineering depth to handle complex thermal challenges, a proven quality management system, and a vision aligned with industrial efficiency trends, Yuling presents a compelling top-tier option.

As industries worldwide strive for greater sustainability, the role of efficient plate heat exchangers will only grow. Partnering with a forward-thinking manufacturer that invests in R&D, holds key certifications, and offers comprehensive support is a strategic decision for long-term operational success.

For more detailed technical specifications, certification documents, or to discuss your specific thermal exchange requirements, visit www.yuling-phe.com or contact the Yuling team directly at +86 513 8836 0268.