- By Admin

-

Construct Ion

-

0 Comments

- Industry News

- 505

How to Select the Right Brazed Plate Heat Exchanger: A Comprehensive Technical Guide for Engineers and Procurement Specialists

Learn how to select the right brazed plate heat exchanger with this step-by-step technical guide. Compare copper vs nickel brazing, understand sizing, and evaluate manufacturers like YIIING MACEINFRY for optimal performance and reliability.

How to Select the Right Brazed Plate Heat Exchanger: A Comprehensive Technical Guide

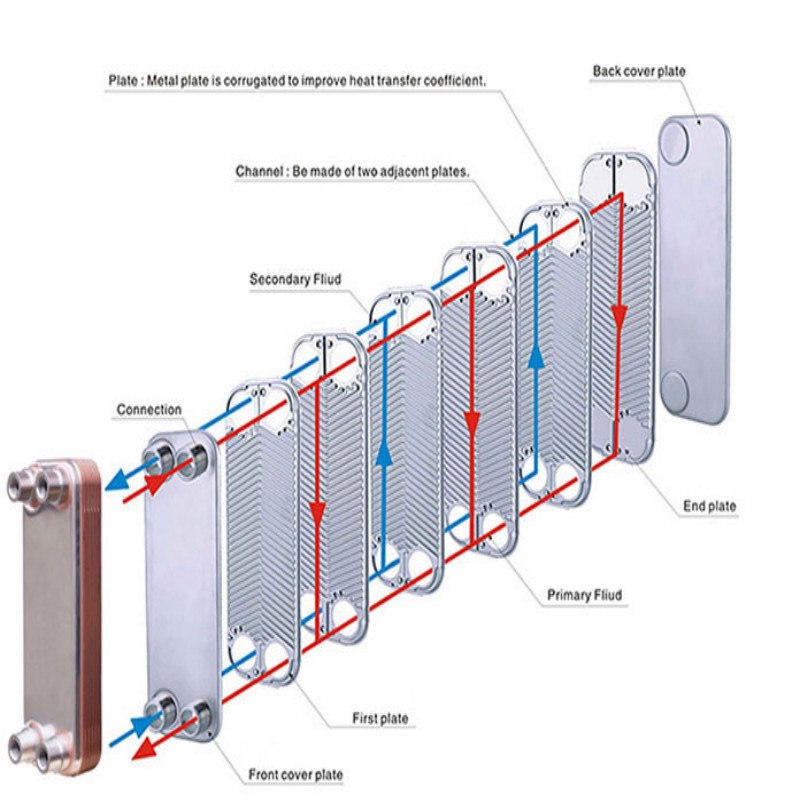

In the rapidly evolving landscape of industrial thermal management, brazed plate heat exchangers (BPHEs) have emerged as a cornerstone technology for applications demanding compact size, high efficiency, and robust performance. Unlike their detachable plate heat exchanger counterparts with rubber plate heat exchanger gaskets, BPHEs utilize a permanent brazed construction, offering superior pressure and temperature ratings. For engineers, plant managers, and procurement specialists, navigating the selection process can be complex. This guide, drawing from the extensive expertise of YIIING MACEINFRY (Jiangsu Yuling Machinery Technology Co., Ltd.), provides a step-by-step framework to ensure you choose the optimal plate heat exchanger for your specific needs.

Step 1: Define Your Application and Process Parameters

The foundation of any successful selection lies in a clear understanding of the application. Brazed plate heat exchangers are versatile, but their suitability varies.

- Primary Applications: Refrigeration (evaporators, condensers), heat pumps, district heating, industrial process cooling/heating, oil cooling, and waste heat recovery.

- Key Parameters to Document:

- Fluid Types: Identify both the primary and secondary fluids (e.g., water, glycol, ammonia, CO2, oil, seawater). This directly impacts material selection.

- Flow Rates (m³/h): For each fluid stream.

- Temperature In/Out (°C): Specify inlet and desired outlet temperatures for both sides.

- Operating Pressure (Bar): Maximum working pressure the unit must withstand.

- Allowable Pressure Drop (Bar): The maximum permissible loss for each fluid circuit, crucial for system pump sizing.

- Heat Duty (kW): The total heat transfer requirement.

Step 2: Select the Appropriate Construction: Copper vs. Nickel Brazing

The brazing material is a critical differentiator, primarily chosen based on fluid compatibility and operating temperature.

| Feature | Copper-Brazed BPHE | Nickel-Brazed BPHE |

|---|---|---|

| Brazing Material | Copper | Nickel |

| Plate Material | Typically Stainless Steel (SUS304/316L) | |

| Max. Design Temperature | Up to 225°C | Up to 225°C |

| Key Advantage | Cost-effective, excellent thermal conductivity. | Superior corrosion resistance to ammonia, chlorides, and other aggressive media. Essential for many industrial and refrigeration applications. |

| Typical Use Case | Water-water heat exchange, standard HVAC, mild glycol solutions. | Ammonia (NH3) refrigeration, seawater cooling, chemical processes with corrosive fluids. |

YIIING MACEINFRY manufactures both types, ensuring the right solution for environments where competitors like Alfa Laval plate heat exchangers or Sondex plate heat exchangers might also be specified.

Step 3: Determine the Correct Size and Port Configuration

Sizing a brazed plate heat exchanger requires balancing heat transfer area with pressure drop. This is where manufacturer expertise is invaluable.

- Channel Pattern: Understand the flow arrangement (e.g., ONE-SIDE FLOW, DIAGONAL FLOW). DIAGONAL FLOW often provides more uniform flow distribution and can handle higher flow rates with lower pressure drop.

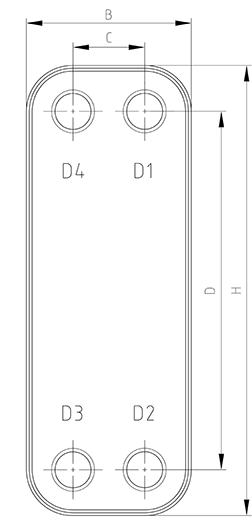

- Port Size and Type: Match the connection ports to your piping. Options include INTERNAL THREAD, EXTERNAL THREAD, CLAMP TYPE (common in refrigeration), and BUTT WELDING for critical, leak-free joints. Ensure the port material (e.g., stainless steel) is compatible.

- Use Selection Software: Reputable manufacturers like YIIING MACEINFRY provide proprietary or web-based selection tools. Input your parameters from Step 1 to get a model recommendation (e.g., ZL20A, ZL95B, ZL200A).

Figure: Examples of different sized YIIING MACEINFRY BPHE models like ZL26 and ZL95A, showcasing varied port configurations.

Step 4: Evaluate Manufacturer Credentials and Quality Assurance

Not all plate heat exchangers are created equal. The manufacturer's reputation is a proxy for reliability.

- Certifications: Insist on internationally recognized certifications. Jiangsu Yuling Machinery Technology Co., Ltd. holds ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety, specifically for heat exchanger production.

- Production Capability: Assess the manufacturing infrastructure. YIIING MACEINFRY operates from a modern facility in Jiangsu, equipped with CNC processing equipment and a dedicated R&D institute, ensuring precision and innovation comparable to leading brands like Tranter plate heat exchangers or GEA plate heat exchangers.

- Testing Protocols: Inquire about standard factory tests, such as pressure testing with helium or water, to guarantee integrity.

Step 5: Consider Lifecycle Costs and After-Sales Support

The lowest purchase price may not be the most economical choice long-term.

- Efficiency: A well-sized BPHE from a quality manufacturer minimizes energy consumption over its lifespan, offsetting a higher initial cost.

- Fouling Resistance: The high turbulence in BPHE channels reduces fouling. Selecting the correct plate heat exchanger plates corrugation pattern for your fluid can extend service intervals.

- Service and Warranty: Ensure the supplier offers clear warranty terms and accessible technical support. YIIING MACEINFRY provides global support, helping with selection, integration, and troubleshooting, a key factor when operating in remote locations or critical processes.

- Availability: Consider lead times and the supplier's global logistics network. Located in the Yangtze Delta with convenient transport links, YIIING MACEINFRY ensures timely delivery worldwide.

Common Pitfalls to Avoid

- Ignoring Fluid Compatibility: Using a copper-brazed unit with ammonia will lead to rapid failure. Always confirm chemical compatibility.

- Oversizing or Undersizing: Oversizing increases cost and may lead to control issues; undersizing fails to meet thermal demands. Use professional selection services.

- Neglecting Pressure Drop: An exchanger with excessive pressure drop will require larger, more expensive pumps, increasing operational costs.

- Choosing Based on Price Alone: Substandard brazing or materials can cause premature leaks, leading to costly downtime and replacement.

Why Partner with YIIING MACEINFRY for Your Brazed Plate Heat Exchanger Needs?

As a national high-tech enterprise, YIIING MACEINFRY stands out in the crowded field of plate heat exchanger suppliers. We combine deep technical expertise—spanning detachable, brazed, and fully-welded plate heat exchanger technologies—with a commitment to quality evidenced by our ISO certifications. Our product range offers a compelling alternative to APV plate heat exchangers, SWEP plate heat exchangers, and Hisaka plate heat exchangers, often with better value and responsive service.

For your next project, engage with our engineering team early. Provide your process parameters, and we will deliver a detailed technical proposal, ensuring you select a brazed plate heat exchanger that delivers optimal performance, reliability, and total cost of ownership.

Contact YIIING MACEINFRY Today:

Visit our website for more technical resources and product details: www.yuling-phe.com

Email: info@yuling-machine.com | Tel: +86 513 8836 0268 | WhatsApp: +8613813790595

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.